The rainy season brings more than just gray skies—it introduces real safety concerns for fuel stations. Wet surfaces, electrical hazards, and the risk of fuel contamination can disrupt operations and endanger both staff and customers. These problems often build up gradually if not addressed with proper preparation. Rainy-day safety precautions aren’t about overreacting; it’s about being ready. With the right precautions, you can prevent accidents, protect equipment, and keep your station operating safely through unpredictable weather. Here are the key measures every fuel station should consider when the rain begins to fall.

Slippery Surfaces: Protect Customers and Staff

When rainwater starts pooling around the forecourt, walkways, and drive areas, the risk of slips and falls rises sharply. Make sure drainage systems are working properly and that surface water doesn’t collect in areas where customers walk or vehicles pass through. Anti-slip mats at walkways, visible caution signage, and frequent mopping of indoor spaces like the convenience store or restroom areas can help prevent accidents. Staff should also wear slip-resistant footwear during their shifts to stay safe.

Fuel Spill Risks Increase When It Rains

During wet weather, rainwater can mix with spilled fuel or leaked oil, creating hazardous puddles. These not only increase slip risks but also spread fuel more widely, making clean-up harder and more dangerous. Fuel attendants must be trained to respond quickly to small spills using absorbent pads or spill kits. Keep spill kits stocked and easy to access, especially during the rainy months when spill spread becomes harder to control.

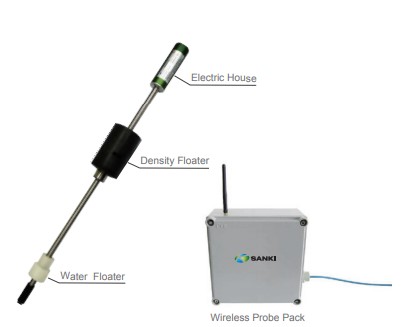

Water Contamination in Underground Tanks

Rain can also pose a threat to fuel quality. If manhole covers are loose, cracked, or poorly sealed, water can seep into underground tanks. This leads to fuel dilution or microbial growth that damages engines and fuel systems. It’s essential to inspect and seal manhole covers properly before and during the rainy season. Covers with watertight gaskets and secure locking systems can prevent this kind of contamination from ever becoming an issue.

Electrical Equipment and Power Supply

Fuel stations depend on reliable power for pumps, lighting, POS systems, and leak detectors. Heavy rain or flooding can damage wiring, trigger short circuits, or knock out systems altogether. Make sure that all outdoor electrical components are weatherproof and elevated above flood levels if your station is prone to water buildup. It also helps to have backup power or surge protectors ready to keep essential systems running.

Final Thoughts

Rainy days are inevitable, but the issues they bring don’t have to disrupt your operations. With the right preparation, your fuel station can remain safe, efficient, and fully functional even in bad weather. At TOIC Solutions, we understand the challenges stations face during the rainy season, which is why we provide reliable tools, equipment, and expert support to help you stay ahead. Whether you’re reinforcing safety measures or upgrading your setup, we’re here to keep your station protected and ready for any downpour.

Why Choose TOIC Solutions?

Trans-Overseas Industrial Corporation (TOIC) Solutions, established in 1976, has been the trusted partner for fuel dispensers, fuel pumps, service station equipment, and the gas station industry in the Philippines. As a leading distributor of advanced fueling technology, we provide reliable, efficient, and durable solutions that enhance the performance of your fueling operations.

With years of expertise and strong partnerships with multinational corporations, TOIC delivers top-quality products, including automatic tank gauging, tank calibration, wetstock management, POS service station systems, and tank testing. If you’re looking to upgrade your fueling system, reduce operational costs, and ensure precision in every transaction, TOIC Solutions is the name to trust. Talk to us!